Zinc dust may look like a dull grey powder, yet it has many uses. This fine metal supports steel protection, chemical reactions, and longer product lifespans. Turning solid zinc into clean powder requires careful planning and skilled control. Each step follows strict rules to keep performance stable and handling safe. A professional zinc dust manufacturer relies on tested systems to meet industrial needs.

Common Processes Used by a Zinc Dust Manufacturer

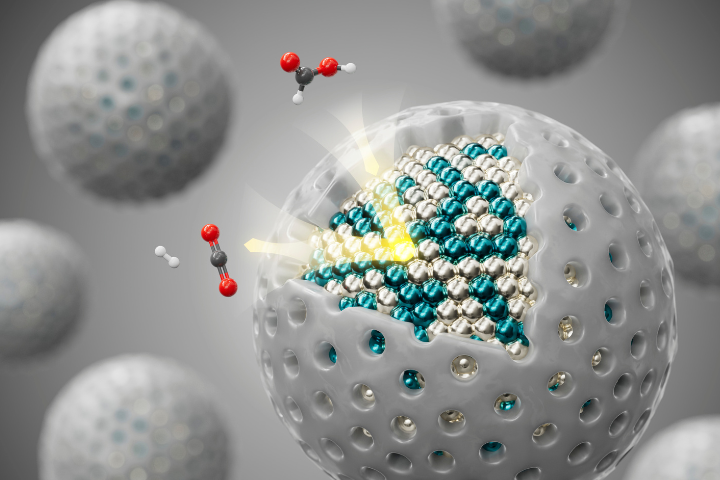

Professional producers primarily rely on two advanced techniques to create zinc dust. Which are distillation and atomization. The choice between them depends on the desired particle characteristics and purity levels.

- Distillation

Distillation creates the cleanest and smoothest zinc dust particles available. The process starts by heating zinc ingots past their boiling temperature. Vaporized zinc cools quickly inside controlled chambers filled with inert gas.

Cooling turns vapor into tiny, round particles with an even surface structure. This shape improves chemical reaction speed and coating strength significantly. Modern systems run continuously to save energy and reduce material waste.

- Atomization Method

Atomization focuses on speed and volume rather than perfect particle shape. Molten zinc flows through nozzles and meets powerful gas streams. These streams break metal into droplets that harden into powder quickly.

Particles from this process appear larger and less uniform overall. Factories often label this output as zinc powder instead of dust. Special tools like ultrasonic systems create powders with unique properties.

- Sorting and Quality Control

Fresh powder contains many particle sizes that require careful separation. Advanced screens sort material into grades with exact size ranges. Correct sizing affects paint settling, reaction speed, and product stability.

Modern sifters handle ultra-fine meshes while reducing fire risk. Static control systems help keep workers and equipment protected.

- Testing for Consistent Quality

Each batch faces strict testing before storage or shipment begins. Metallic zinc levels often reach above ninety-seven percent purity. Laser tools confirm particle size matches required grade standards. Chemical checks ensure lead and cadmium stay extremely low. Certified products follow global rules such as ASTM classifications.

The zinc dust manufacturer uses a trusted system to produce it with precision. Careful processing turns raw metal into dependable industrial material. These processes support stronger and more reliable products worldwide.